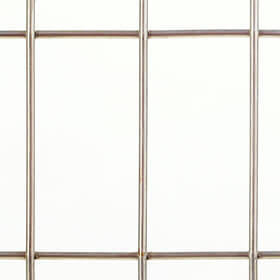

Wire mesh is an extremely popular choice for infill panels and railings applications. When properly framed and installed, wire mesh infill panels serve as a protective barrier in high traffic areas, like jogging paths, zoos, stadiums, recreational parks, college institutions, amusement parks, restaurants, bars and even residential patios and decks. Engineers and designers often specify wire mesh because it offers an excellent combination of visibility and safety.

Because each infill panel requirement is different, customers will supply full specifications, including the desired mesh or opening size, diameter wire and sheet size. Of course, it is the responsibility of the customer that the provided specifications meet all appropriate state and local building ordinances.

Selecting the appropriate material is critical when deciding to use wire mesh for infill panels – stainless steels, plain steel and galvanized are very popular. Other metals and alloys, such as copper and its alloys, are sometimes used to create an upscale look, particularly in high-end restaurants or residences.

Identifying the appropriate combination of opening size and diameter wire is also important. Opening sizes tend to range from approximately 4″ square opening to 1/2″ square opening, with 2″, 1-1/2″ and 1″ opening sizes preferred by many. Similarly, diameter wires range from .250″ to .063″. Larger opening sizes tend to employ heavier diameter wires.

By and large, wire mesh used in infill panels tends to be custom manufactured simply because there are hundreds of different wire mesh specifications that are often utilized. Custom manufacturing conveniently allows for the production of a specific opening size and diameter wire in the material of the customer’s choosing. Darby specializes in custom manufacturing both woven and welded wire mesh, and routinely provides quick lead times and competitive pricing. Darby normally offers custom wire mesh in weaving crimp styles such as plain, intermediate and lock crimp or in the standard welded construction.

Should you have a particular specification in mind, please contact us to discuss your requirements.

To better serve our customer, Darby stocks a wide array of various wire mesh specifications that can be used as infill panels and in railing applications. The options listed on this website represent a handful of the more popular items that are available from stock or through custom manufacturing.

Connect with Darby